Interactive Manual Placement

Drag, Drop & Rotate

Automated vs Real-World Loading

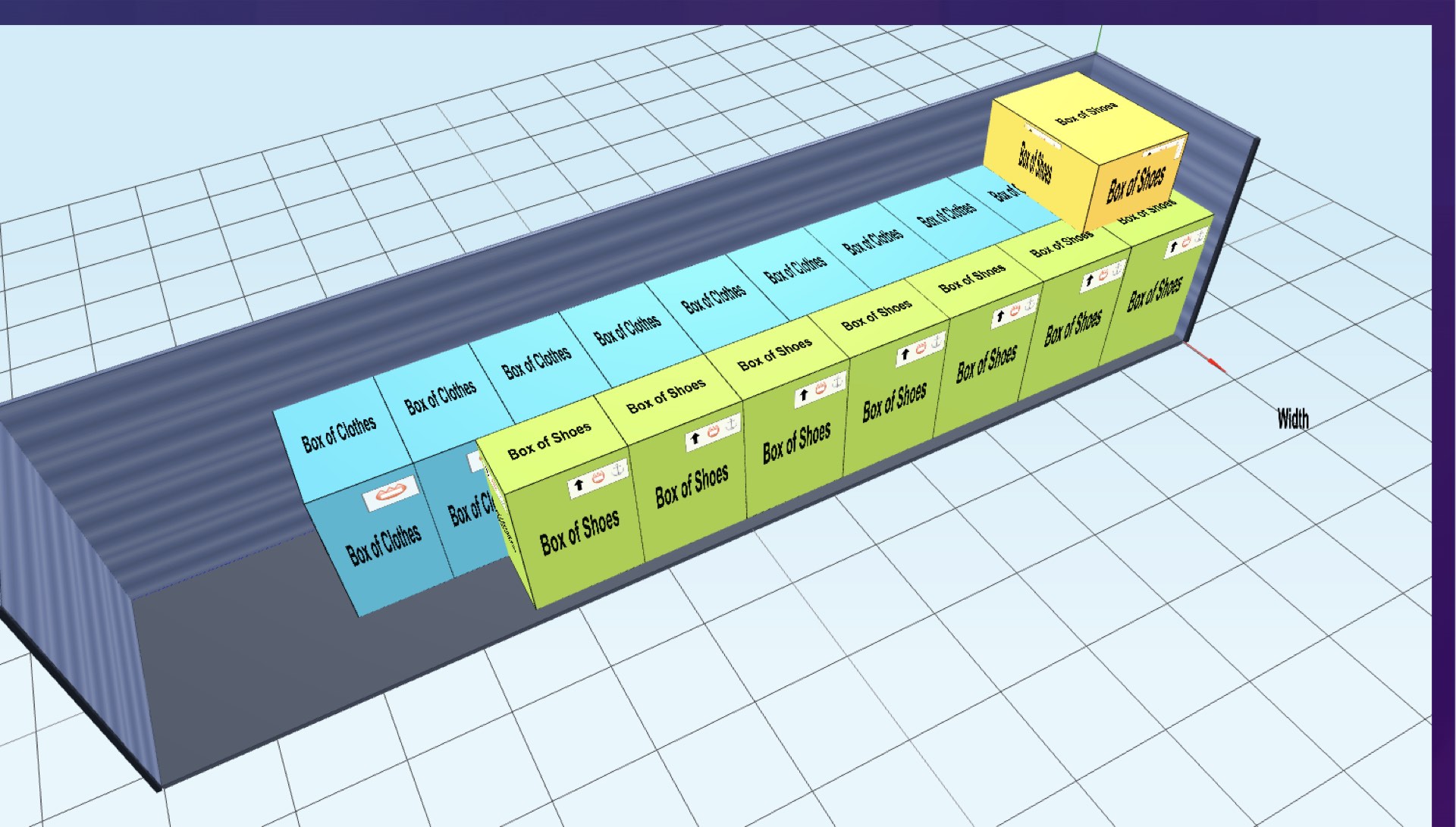

Automated packing algorithms provide excellent starting points, but warehouse professionals often need to adjust placements based on real-world constraints, loading sequence requirements, or operational preferences. Traditional 3D packing tools don't allow modifications after optimization, forcing users to accept algorithmic decisions even when manual adjustments could improve efficiency or accommodate specific loading procedures that automated systems can't anticipate.

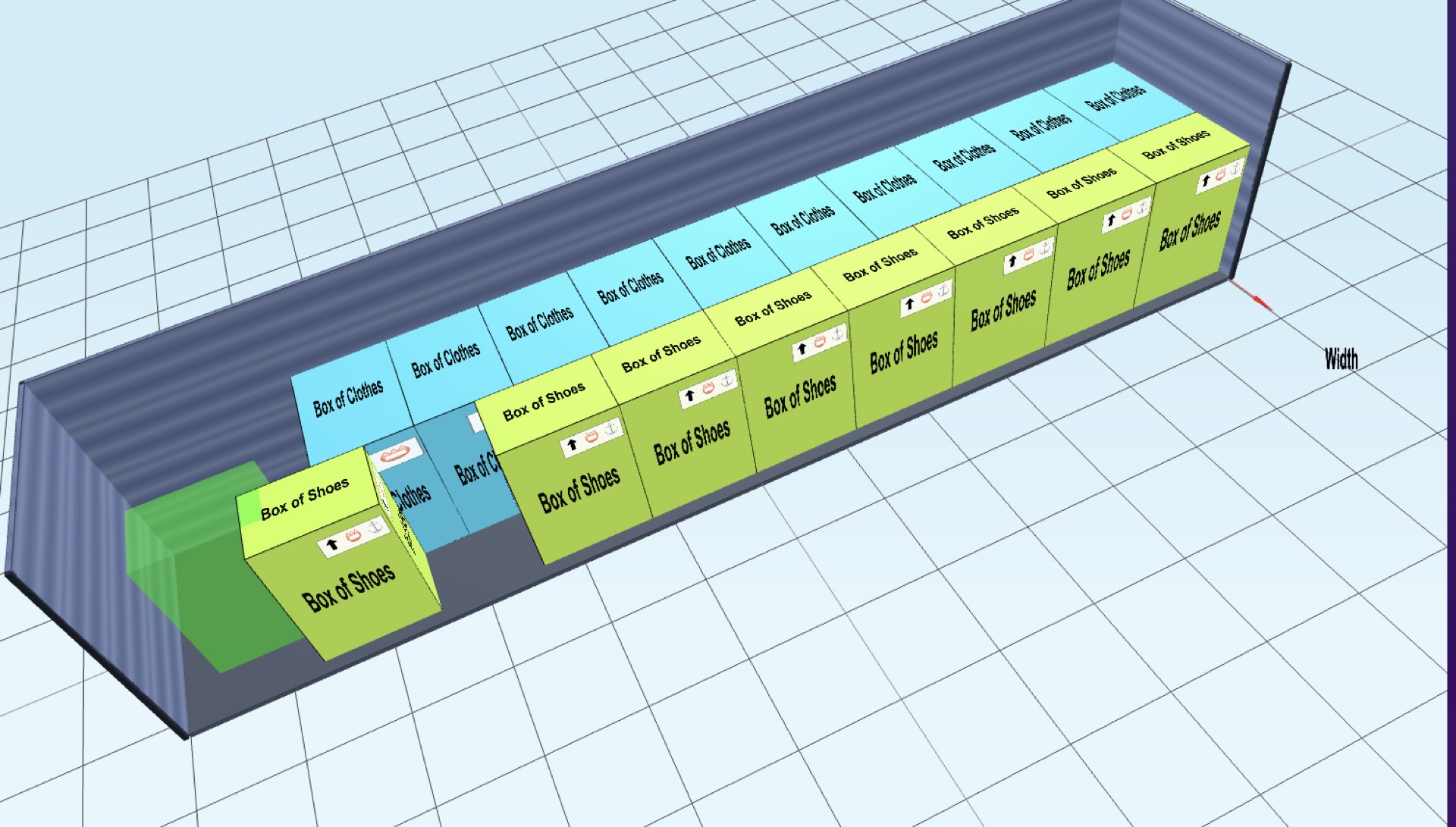

Physics-Based Manual Control

3DPACK.ING's manual placement system gives you complete control over item positioning with intuitive drag-and-drop functionality and precision rotation controls. Click any item to grab it, drag to reposition, and use rotation controls to achieve the perfect orientation. The system includes real-time collision detection that prevents impossible placements while allowing you to explore alternative arrangements and apply warehouse expertise to optimize the automated solution.

Enhanced Loading Flexibility

This interactive approach combines algorithmic efficiency with human expertise, delivering superior loading solutions. You can test different arrangements quickly, accommodate specific loading sequences, and apply practical knowledge that automated systems might miss. The physics-based validation ensures all manual adjustments remain feasible while giving you the freedom to optimize based on operational requirements, equipment constraints, or cargo handling preferences that only experienced warehouse professionals understand.

Advanced Manual Placement Features

- Drag-and-Drop Interface: Intuitive click-to-grab system for moving items to new positions within the container

- Six-Orientation Rotation: Precise rotation controls allowing items to be oriented in all six possible directions

- Real-Time Collision Detection: Physics engine prevents impossible placements and maintains spatial integrity

- Snap-to-Grid Positioning: Optional grid alignment for precise placement and organized loading patterns

- Multi-Item Selection: Select and move multiple items simultaneously for efficient rearrangement

- Undo/Redo Support: Experiment freely with ability to revert changes and explore different scenarios

Take Control of Your Loading Process

Combine algorithmic optimization with warehouse expertise. Start using interactive manual placement for superior container loading today.

Try Manual Placement