E-commerce Box Optimization: Stop Wasting Money on Oversized Boxes

Find the perfect box size for every order - reduce costs like Amazon and major retailers

The Hidden Cost of Wrong-Sized Boxes

Every inch of empty space in your shipping boxes represents a direct hit to your bottom line. From wasted materials to inflated shipping fees, the cost of inefficient packaging adds up. Our AI-powered tool eliminates this waste by instantly identifying the smallest viable box for any combination of items, mirroring the sophisticated optimization systems of e-commerce giants. This is a game-changer for:

- E-commerce Stores: Dramatically reduce box inventory and outbound shipping costs.

- Amazon FBA Sellers: Minimize costly dimensional weight (DIM) charges and improve margins.

- 3PLs & Fulfillment Centers: Streamline pick-and-pack operations and increase throughput.

- Subscription Box Companies: Standardize packaging to improve cost efficiency and customer experience.

- Box Costs: Up to $2.00 per shipment on needlessly oversized boxes.

- Void Fill: An extra $0.50 per package just to fill empty air with packing peanuts or pillows.

- DIM Weight Penalties: Paying up to 40% more in carrier fees for bulky, half-empty packages.

- Wasted Labor: 30+ seconds of packer guesswork on every single order.

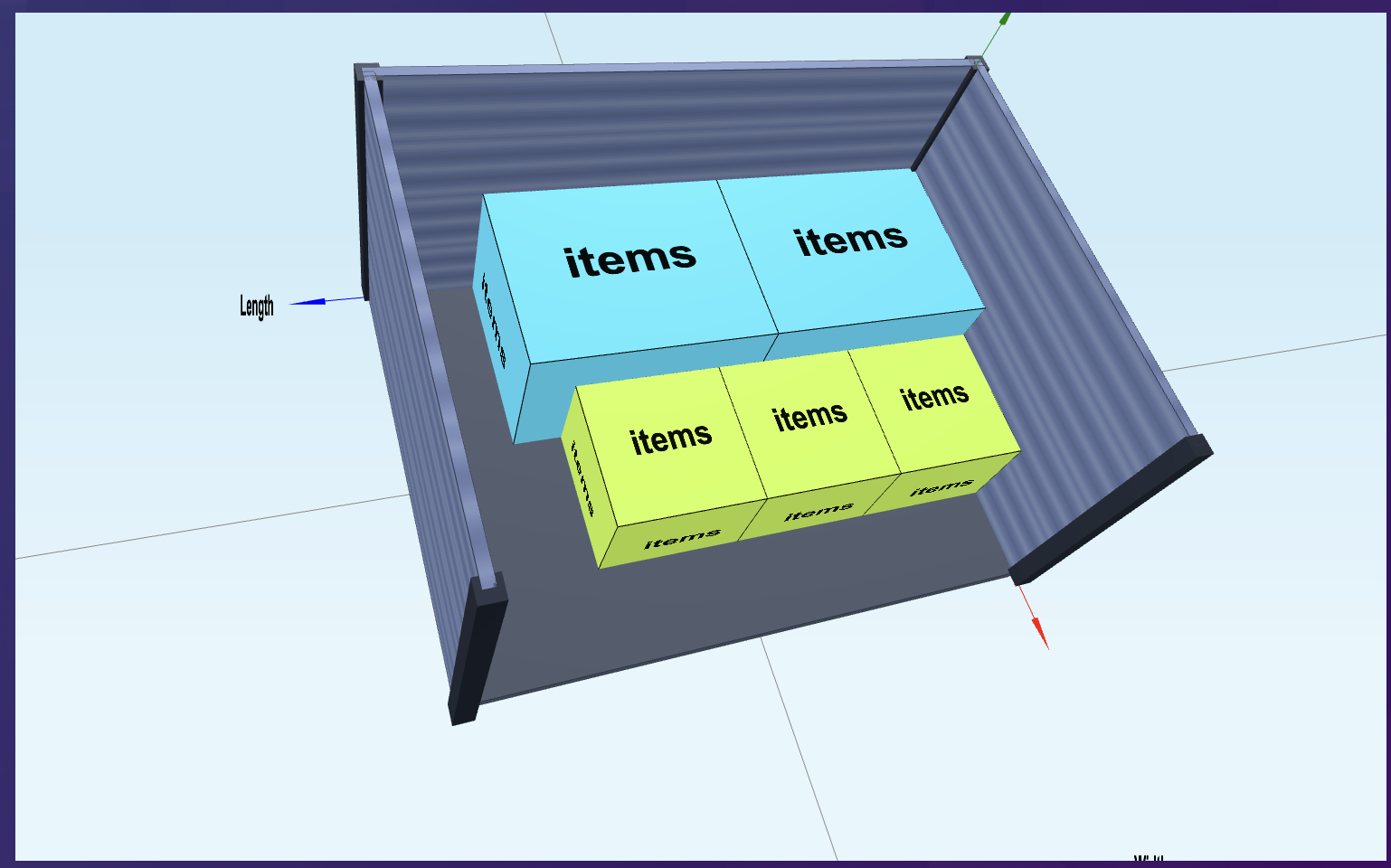

E-commerce Box Selection Example

Imagine a common scenario: an order comes in, and your packer has to choose from your standard box inventory. Which one is the right fit?

Find the best one:

- 12 x 9 x 6 (small box)

- 16 x 12 x 8 (medium box)

- 20 x 16 x 12 (large box)

Customer ordered:

2 items of 5 x 4 x 3

3 items of 3 x 3 x 2

Empower your warehouse team to make the right choice every time. Instead of defaulting to a larger, "safe" option, our system provides an instant, data-backed decision that cuts material costs and slashes dimensional weight fees.

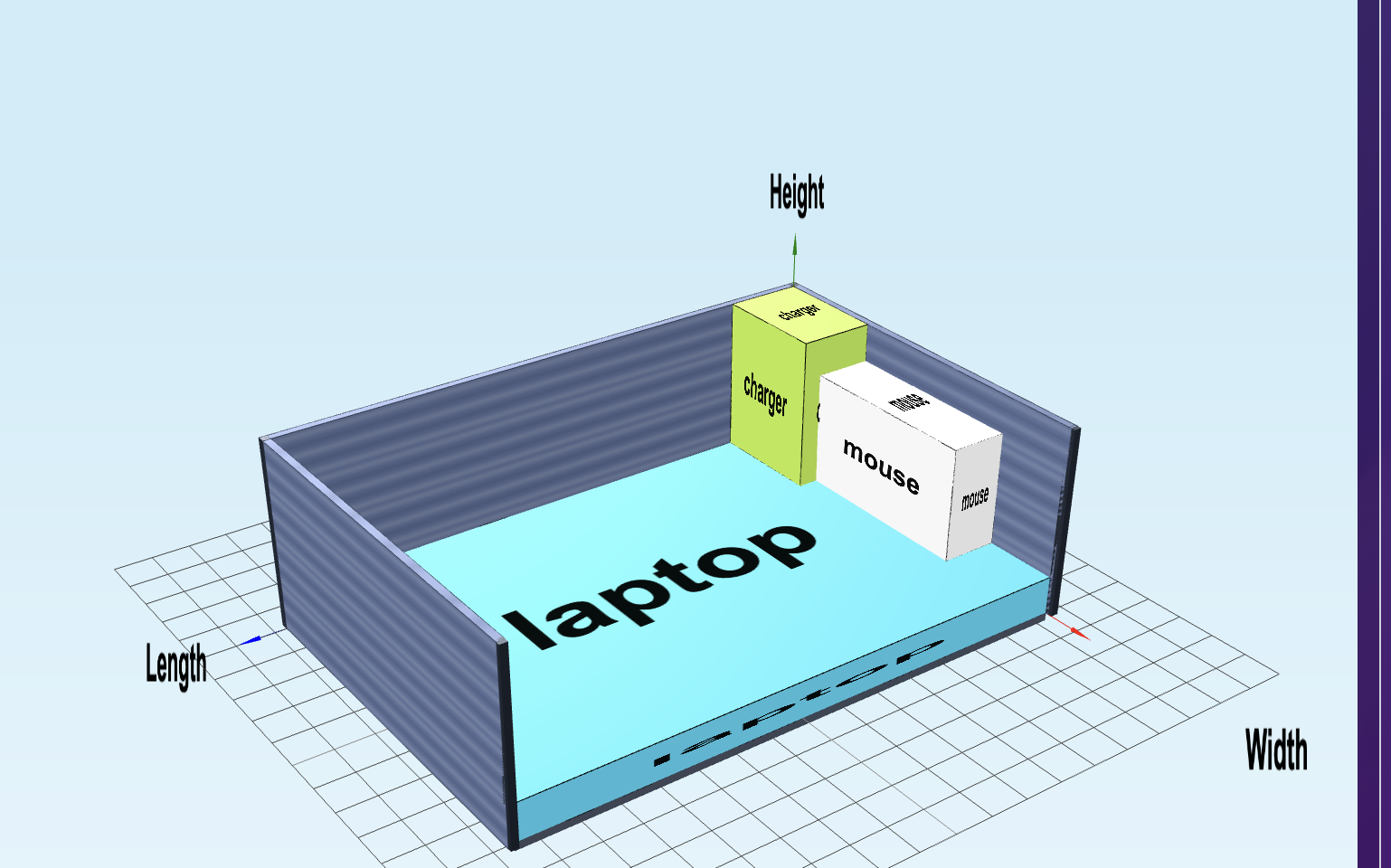

Custom Box Size Recommendation

What if you don't have a perfect-fit box? Our tool helps you design a better inventory. By analyzing a typical order, it can recommend the ideal custom box size to stock.

Customer order:

1 laptop 15 x 10 x 1

1 charger 4 x 3 x 2

1 mouse 5 x 3 x 1.5

find the best container with minimum width and length?

Leverage this insight to refine your packaging supply. By stocking box sizes that are mathematically aligned with your most frequent order combinations, you can systematically reduce costs across your entire operation.

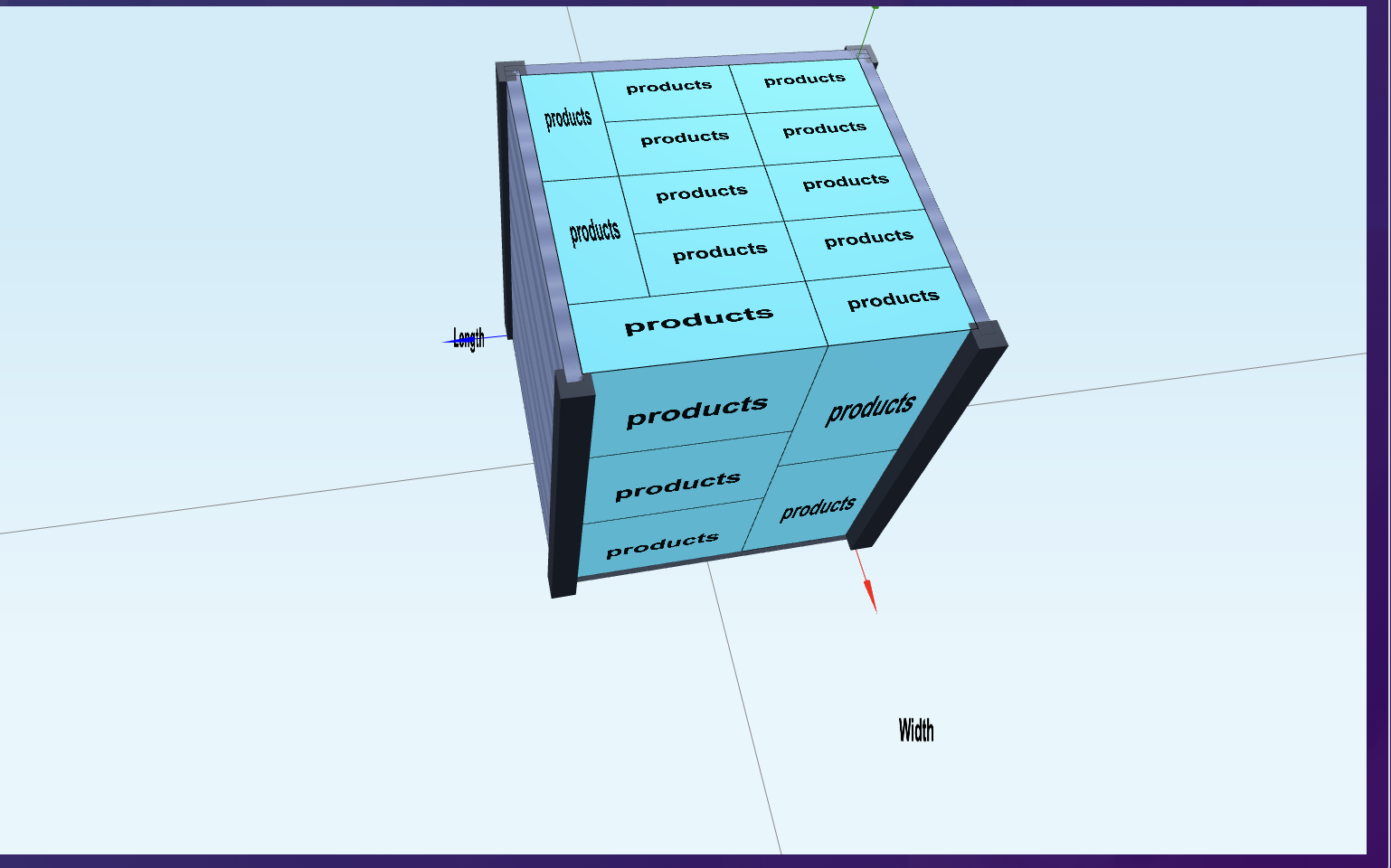

Subscription Box Optimization

For subscription box companies, consistency and efficiency are paramount. How do you choose a standard box size that maximizes the number of products you can include?

Monthly beauty box items:

- 5 x 5 x 6 (standard box)

- 4 x 5 x 5 (eco box)

max quantity of products 2 x 1 x 3?

ignore weights

This is the ideal tool for balancing product value, unboxing experience, and packaging costs, ensuring your subscription service remains profitable and competitive.

How It Works

Our system is designed for ease of use. It processes simple, natural language queries to solve complex packing problems, considering:

- Advanced 3D packing algorithms that test thousands of potential orientations.

- All possible item rotations (on length, width, and height) to find the tightest fit.

- A primary focus on maximizing container volume efficiency to reduce empty space.

- Real-world constraints to ensure the suggested pack is physically possible to load.

Just type what you need:

- "Find the best container" to instantly compare your stock boxes and get the most cost-effective recommendation.

- "Max quantity" to determine exactly how many of a single SKU can fit into a specific box.

- "Find the best one: [list]" to compare a specific list of boxes and see which is the optimal choice for an order.

- "[items], find the best container?" to discover the minimum box dimensions needed for a multi-item order, perfect for sourcing new packaging.

Real Business Impact

- Slash Shipping Costs: Cut carrier fees by 15-30% by eliminating dimensional weight penalties.

- Boost Efficiency: Free up hours of manual guesswork for your packing team.

- Increase Accuracy: Eradicate costly errors from packers choosing the wrong box size.

- Optimize Inventory: Make data-driven decisions about which box sizes to stock and which to eliminate.

Real E-commerce Success Stories

"We were able to reduce our average box volume by 40%, leading to annual packaging cost savings of over $180,000. Our customers also appreciate our commitment to less wasteful packaging." - Online Electronics Retailer (50K orders/month)

"As an Amazon FBA seller, DIM weight charges were eroding our margins. 3DPACK.ING was instrumental in helping us identify the most efficient box sizes for our catalog, saving us an average of 30% on FBA fulfillment fees." - Amazon Top 1000 Seller

"Our pick-and-pack time per order has dropped by nearly 25%. Workers don't have to guess anymore; the system gives them the correct box choice instantly, which has been a huge boost to our warehouse throughput." - 3PL Warehouse Manager

Advanced E-commerce Use Cases

Multi-SKU Order Optimization

A customer places a complex order with multiple different items. Which of your standard boxes is the most economical choice?

Customer order from your store:

- 2 x phone cases (4 x 2 x 0.5)

- 1 x wireless charger (5 x 5 x 1)

- 3 x cables (6 x 1 x 0.5)

Find the best box from inventory:

- Small: 8 x 6 x 4

- Medium: 10 x 8 x 6

- Large: 12 x 10 x 8

- XL: 16 x 12 x 10

Returns Processing

How do you size a prepaid return box? Account for the original item's dimensions plus a buffer for customer repacking to ensure a smooth returns process.

Return shipment sizing:

- Original item: 12 x 8 x 4

- Plus 20% padding for customer repack

What size prepaid return box?

Kitting and Bundles

You're creating a new holiday gift set. What are the absolute minimum dimensions required for a custom gift box that includes all components and accommodates gift wrap?

Holiday gift set contains:

- 1 main product (8 x 6 x 3)

- 3 accessories (2 x 2 x 1 each)

- Gift wrap adds 0.5" per dimension

What's the minimum gift box size needed?

ROI Calculator for E-commerce

The numbers speak for themselves. Consider a business shipping just 1,000 orders per month:

- Box Cost Reduction: $500 - $1,500 per month

- Shipping Savings (DIM Weight): $2,000 - $5,000 per month

- Void Fill Reduction: $200 - $500 per month

- Labor Efficiency Gains: 8 - 15 hours saved per month

- Estimated Annual Impact: A staggering $32,400 to $84,000 added back to your bottom line.

Ready to Stop Shipping Air and Start Saving?

Transform your packaging from a costly expense into a competitive advantage. Implement the same level of optimization used by the world's largest retailers.

Start Your Free TrialNo credit card required. See a tangible return on investment within your first week.